Perception and performance

Finding the right sustainable products for your brand

Navigating the array of sustainable options on the market today requires some effort in understanding which products will help you to drive the performance your business needs. It also requires some due diligence to see beyond many of the claims being made regarding environment impact and what’s actually best for your application. We take a comparative look at paper pallet wrap and plastic machine pallet wrap, considering features such as durability, strength, flexibility, cost and much more. What are the potential gains and what would be best for operational performance as well as your sustainability goals?

Paper Pallet Wrap vs Plastic Pallet Wrap on Cost

When it comes down to this very important comparison – it’s not so straight forward as there are a few things to consider. We break it down here for you

How much does paper pallet wrap cost?

Using paper pallet wrap will always be a lot more expensive than its plastic wrap counterpart. So why is this? When comparing the materials themselves, and the actual amount of product required to wrap pallets effectively, more paper will always be required to achieve pallet stability.

Paper pallet wrap is much heavier in physical weight than plastic, especially high-performance machine wrap for power stretch machines such as iWrap which is now available in just 9 microns. This extra weight and the amounts needed to overcome load stability issues with paper could mean dealing with a product 5 to 10 times heavier than plastic pallet wrap.

And this extra weight and volume of product needed translates into costs right across the despatch process, from extended wrapping times to heavier pallets to transport.

How much do paper pallet wrap machines cost?

There is no getting away from it, pallet wrap machines are expensive irrespective of whether you’re using paper or plastic. Traditional plastic pallet wrap machines have been around since the 1970’s and have advanced to the inline or robot wrappers used today on production lines and in warehouses today.

Pallet wrap itself has also advanced, especially with the introduction of high-performance film which sees even greater yields from pallet wrappers due to its stretch capabilities. Equipment outlay costs are anywhere from £5,500 to £15,000 depending on the model.

When it comes to paper pallet wrap machines, which is a fairly new introduction to the market, the cost increases significantly. Costs can be anywhere from £40,000 to £75,000 and many find this expense prohibitive, but this could be a justified expense depending on your sustainability goals.

Paper Pallet Wrap vs Plastic Pallet Wrap on Flexibility and Stretch

When it comes to the actual wrapping of products on the production line and in the warehouse, if there is a mixed inventory of irregularly stacked pallets, paper will struggle to accommodate this. Paper works well with products that tend to be light in weight as well as uniformly stacked with regular sized boxes. Paper will struggle on pallets which have mixed or heavy loads as there is little ‘stretch’ or ‘give’ to enable the paper to wrap effectively using the least amount of product possible. As it does not self-cling, like plastic pallet wrap, it does make this process even more complicated, sometimes even requiring additional products such as tape to keep it secure and in place.

In comparison, plastic pallet wrap is exceedingly efficient when used to wrap these types of irregular pallets. We mentioned yield earlier, and it is this flexibility and stretch that means a close effective wrap around the products using the least amount of product possible. The self-cling also means no additional products are required after wrapping.

As well as the volume of materials needed for effective wrapping and reliable load stability – this brings us back to our first point again – cost.

Cost and stretch capacity cannot be viewed in isolation. As discussed, high performance pallet wrap has a significant yield or stretch capability of up to 300%+. This means a 3000-meter roll transforms into 10,000 meters when used correctly on the right machine.

A 3000-metre roll of paper pallet wrap would potentially be capable of a stretch around just 1%, providing a not so generous 3030 metres.

What does this mean? Using paper pallet wrap means having to use up to 3 times more product compared to plastic pallet wrap – which means more expense all round.

Paper Pallet Wrap vs Plastic Pallet Wrap on Durability

Paper pallet wrap is not waterproof and becomes vulnerable when out of your sight during the delivery process. Pallets accidently left out in the rain could result in ruined products and the costs of recall and resupply which could be significant. Paper will also struggle with puncture resistance and overcoming tearing, resulting in pallet wrap failure. If you have a closed loop network or if it can be guaranteed by your delivery service that they will not leave pallets vulnerable to weather, then this could still be a good option for you.

Plastic wrap on the other hand, overcomes these challenges easily, providing excellent protection again dust and moisture. Also, due to its incredible tensile strength, high-performance pallet wrap is far more resistant to damage, protecting products in transport.

Paper Pallet Wrap vs Plastic Pallet Wrap on Manual Handling

Comparing weights of the rolls themselves, a 3000-metre roll of plastic pallet wrap weighs around 16-18 kg. When it comes to moving and loading a 3000-metre roll of paper pallet wrap, manual handling equipment would be needed to manoeuvre it as it would be extremely heavy. We discussed earlier the paper pallet wrap volume needed can be up to 10 times heavier.

To put this into context for you, a 3000-metre roll of high performance machine pallet wrap would be around 250 mm in diameter. An equivalent 3000 metre roll of paper pallet wrap would be over 1 metre in diameter. This really helps to put in perspective the sheer weight and volume of a roll of paper pallet wrap compared to plastic.

Paper Pallet Wrap vs Plastic Pallet Wrap on Environmental Impact

So if you’re looking for some positive news on using paper pallet wrap, you’re probably thinking that finally, this is the section for you! Or is it?

Again, nothing is simple or straightforward, but let’s start with the good news first!

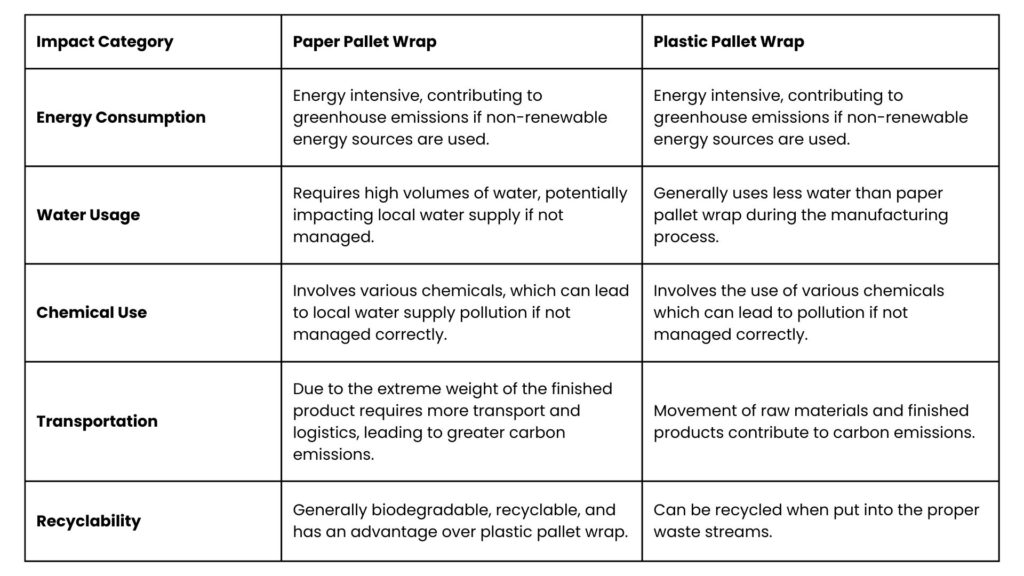

Paper pallet wrap is generally made from renewable sources, and many have FSC® accreditation which is reassuring for buyers looking for products from responsibly managed forests. However, let’s look a little closer and consider the environmental impact of the manufacturing process of paper pallet wrap and how it directly compares with plastic pallet wrap:

This final element of the comparison demonstrates that paper pallet wrap can have a lower overall environmental impact, especially when made from recycled materials and when proper recycling systems are in place. However, the specific impact can vary depending on manufacturing practices and local waste management.

It’s worth noting that plastic wrap is often lighter and more durable than paper alternatives, which can lead to reduced transportation emissions and less materials and water is used overall.

So when it comes to making the best choices for your business, this will depend on your inventory, your local recycling options, specific application concerns (moisture, puncture resistance) product protection, transport rigours and distances and of course – your environmental priorities.

Often what can seem like an environmentally positive product decision for your business just needs a bit more investigation to reach a decision that’s right for you.

Take the Paper Pallet Wrap Test!

Want to see if Paper Pallet Wrap could work for your operation?

It’s just 3 quick questions to find out!

Want to know more? Simply email us at [email protected] for further information, help and support.